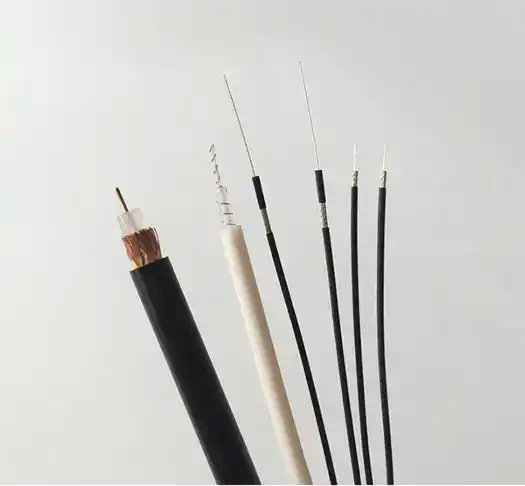

Coaxial cable stripping machine

The coaxial wire stripping machine is a high-precision coaxial wire stripping device. The menu-based dialogue control system allows easy setting of each function, can save 100 types of processing data, has three start modes: button/sensor/pedal, can set up to nine layers of stripping, and has a twisting function at the front end with adjustable speed.

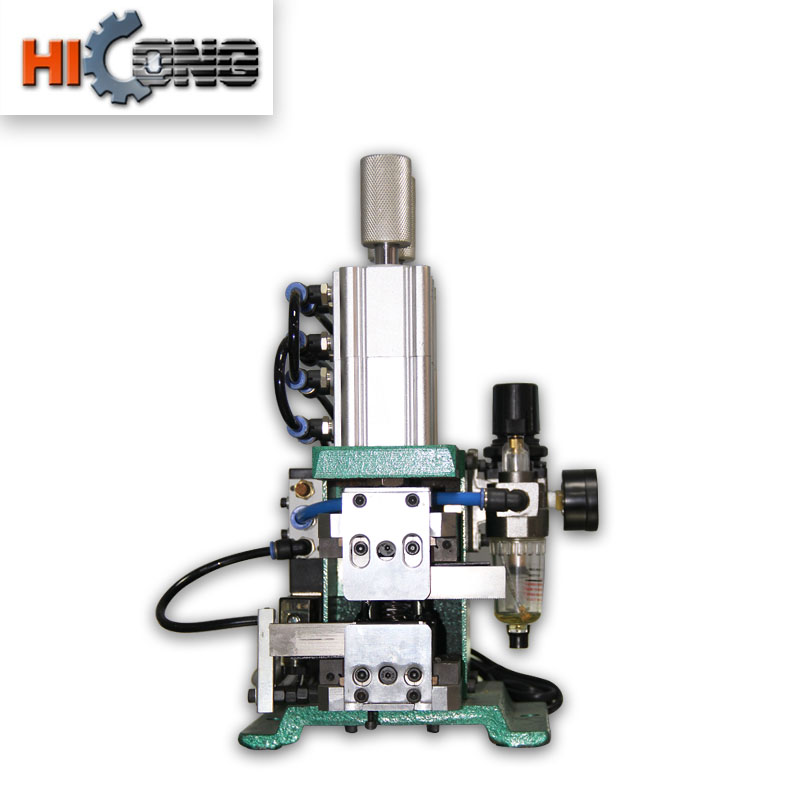

Model: HL-8515

Brand: Hilong

Features:

HL-8515 coaxial wire stripping machine is a high-precision coaxial wire stripping equipment. It adopts intelligent digital photoelectric technology, Japanese NSK ball bearings, screw drive, and uses the company's patented specific coaxial center positioning device. When the user replaces the tool, there is no need to recalibrate the blade, which makes the operation simpler. The menu-based dialogue control system allows for easy setting of each function, can save 100 types of processing data, has three starting modes: button/sensor/pedal, can set up to nine layers of stripping, and has a twisting function at the front end with adjustable speed.

All mechanical parts are imported from Japan and Germany. The wear resistance of the lead screw is 500% higher than that of domestic brands, which makes it more durable and ensures stable product quality. The blades use the world's top heat treatment technology to make them more wear-resistant and stable. The imported calibration equipment strictly controls the straightness and flatness of the blade, with high precision. The thickness tolerance can reach within 0.03 mm. The blade is mirror-finished to ensure that there is no resistance to stripping and the wire cutting is smoother and more beautiful. At the same time, it has the characteristics of labor saving and low noise. The unique three-sided grinding technology of the blade increases the wear resistance by more than 30% compared with other ordinary blades. Each machine can be put into storage and shipped after tens of thousands of simulations.

Specifications:

Dimensions :198X305X650 (MM)

Weight Approx. :25KG

Maximum processing diameter :7 mm

Minimum processing diameter: 0.8 mm

Maximum stripping length 60: mm

Minimum stripping length :0.5 mm

Maximum number of peeling layers :9 layers

Cutting depth unit :0.01MM

Production Depending :on the total length of the operation line and the operation procedure, the minimum can reach 500-1000 PCS/hour

Drive mode :Motor/ball screw drive

Peeling blades :2 pieces, material: imported tungsten steel

Centering blades :2 pieces, material: imported high-speed steel

Wire clamping device :Automatic centering, motor drive, clamping force program control

Starting mode Induction/manual/pedal (optional)

Power: 220V/50HZ 250W

Working environment: 0-50 degrees, moderate dryness, vibration-free work surface

INQUIRY

Categories

Latest News

Contact Us

Contact: Miss.Xin

Phone: 86-13712945876

E-mail: info@Hilong-e.com

Whatsapp:

Add: Guangdong Province, China TianHe District, GuangZhou Num 899