Injection Moulding Machine For Pvc Pipe Fitting Injection Molding Machine

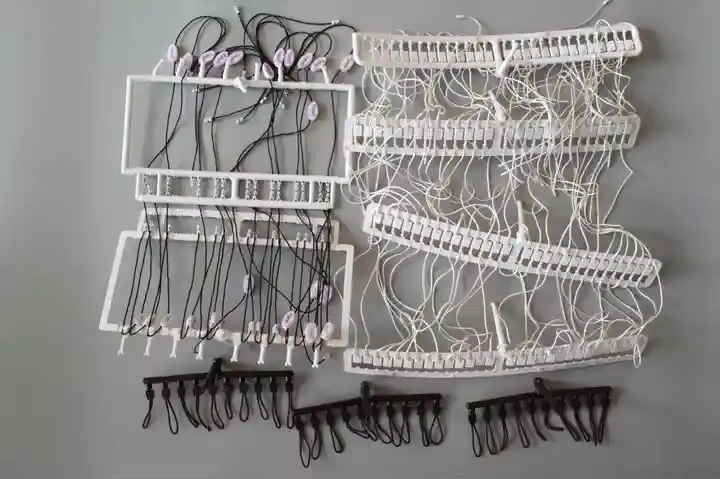

Plastic injection moulding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Model: HL-256

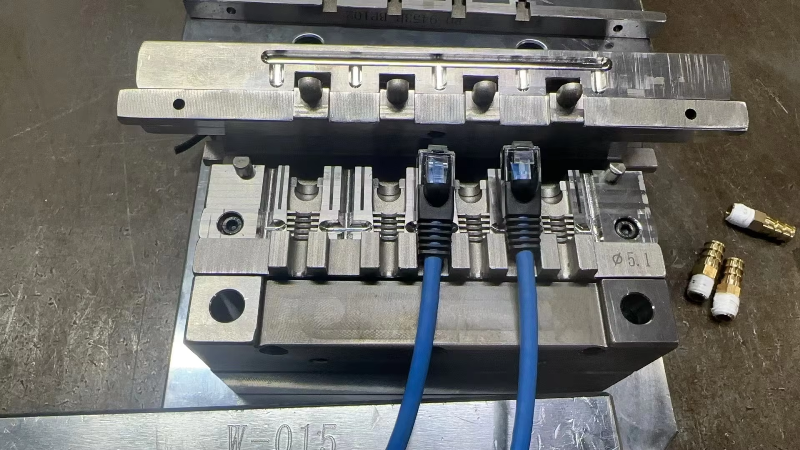

Brand: Hilong

Features:

1.Vertical mold opening and vertical injection, suitable for insert molding.

2, Nitrided mast, material tube, high torque night pressure motor drive, multi-stage injection pressure, good plasticizing performance.

3, Direct pressure mother-mother lock cylinder design, rapid mold clamping, low-pressure safety mold clamping, abnormal automatic mold opening, multiple pressure control, high safety, improve mold life.

4, Electrical warranty device, no mistakes occur, maintenance operators safe.

5, Automatic fault display, maintenance is quick and easy.

6, Electronic control, night pressure face using brand-name parts, quiet, precise and durable.

7, Multi-stage temperature control, multi-stage injection pressure, injection speed, back pressure stepless adjustment, suitable for precision plastic parts molding.

Specifications:

Injection Rate | mm | 115 | ||

Screw Speed Max. | rpm | 0-205 | ||

Nozzle Comtact Force | Tons | 4.45 | ||

Nozzle Retraction Stroke | mm | 170 | ||

Clamping Force | Tons | 35 | ||

Platen Size | mm | 540*380 | ||

Distance between tie bere | mm | 375*205 | ||

Min.Mold Height | mm | 158/58 | ||

Opening Stroke | mm | 180 | ||

Max.Open Daylight | mm | 338/238 | ||

Ejetor Force | Tons | 1.3 | ||

Ejetor Stoke | mm | 35 | ||

Max.Hydaulic Pressure | kg/cm² | 140 | ||

Pump Output | l/min | 34.5 | ||

Oil Resservoir Capacity | l | 100 | ||

INQUIRY

Categories

Latest News

Contact Us

Contact: Miss.Xin

Phone: 86-13712945876

E-mail: info@Hilong-e.com

Whatsapp:

Add: Guangdong Province, China TianHe District, GuangZhou Num 899