Copper Tape for Wire Splicing Machine 2mm

Copper linking tape for wire splicing machine is produced with the production process of cladding-welding- drawing method, by cladding planished copper stripe concentrically on the outer surface of the aluminium core, via several times of drawing and heat treatment, to meet customers' technical requirement on line diameter, mechanical property and electrical property. The copper clad aluminum wire characterizes by both the samll density of aluminum and the good conductivity of copper. This kind of bimetallic composite wire is suited for most electrical conductor applications.The processing method of CCA wire is similar to that of copper wire during cable manufacture.

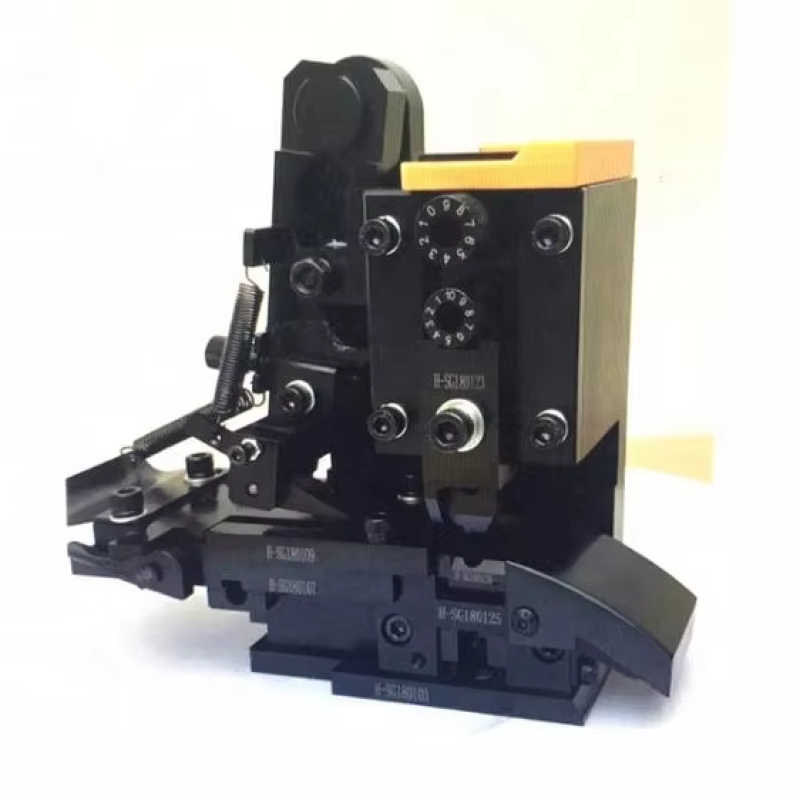

Model: HL-P

Brand: Hilong

Features:

Copper linking tape for wire splicing machine is produced with the production process of cladding-welding- drawing method, by cladding planished copper stripe concentrically on the outer surface of the aluminium core, via several times of drawing and heat treatment, to meet customers' technical requirement on line diameter, mechanical property and electrical property. The copper clad aluminum wire characterizes by both the samll density of aluminum and the good conductivity of copper. This kind of bimetallic composite wire is suited for most electrical conductor applications.The processing method of CCA wire is similar to that of copper wire during cable manufacture.

Specifications:

| Width | 1.0MM~6.0MM |

| Thickness | 0.25MM 0.3MM 0.36MM 0.4MM |

| Width | 1.0MM 1.3MM 1.5MM 2.0MM 4.0MM 6.0MM |

| Thickness | 0.25MM 0.3MM 0.36MM 0.4MM |

| Standard | ROHS and all kinds of Environment requirement |

INQUIRY

Categories

Latest News

Contact Us

Contact: Miss.Xin

Phone: 86-13712945876

E-mail: info@Hilong-e.com

Whatsapp:

Add: Guangdong Province, China TianHe District, GuangZhou Num 899