Full automatic Double wire combined terminal crimping machine

Full automatic terminal crimping machine, using high-tech frequency conversion technology, electronic precision positioning, when pressure welding machine working noise is smaller than the traditional terminal, and save electricity, the variable is more convenient and quick, avoid the traditional terminal clutch, cable lug crimping machine.

Model: HL-HY02

Brand: Hilong

Features:

1. Full automatic terminal crimping machine

2. Built-in frequency converter, high speed and low noise

3. One machine is suitable for various terminals, very easy to change mold.

4. Support manual mode and automatic mode, you can adjust the machine easily in manual mode.

5. LED display will show how many terminals have been crimped.

6. Speed is adjustable, crimping die designed according to your requirement.

Specifications:

Model | HL-HY02 |

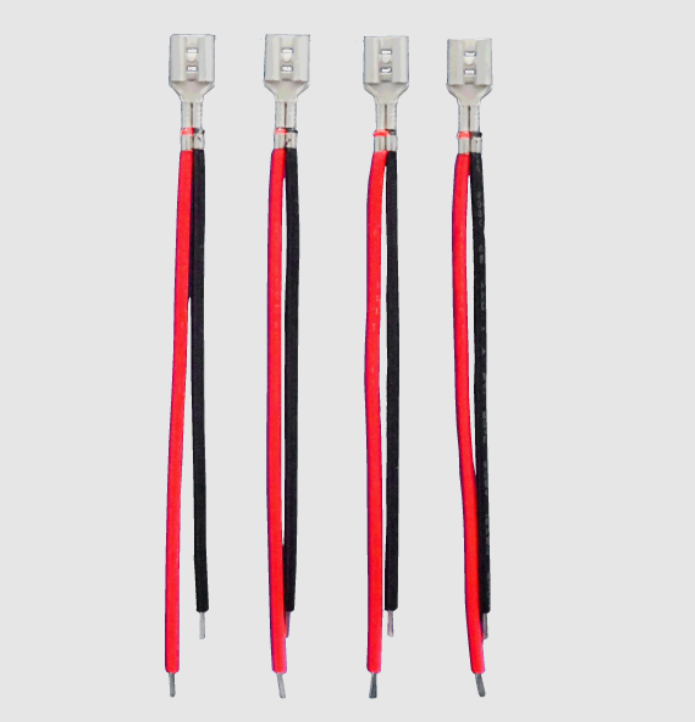

Name | Full automatic Double wire combined terminal crimping machine |

Function | Double wire combined terminal crimping machine |

Size | 1000L*750W*1650H |

Weight | 400KG |

Display | Color LCD touch screen |

Mode of operation | Auto run + manual operation |

Blade adjustment method | Motorized adjusting |

Blade material | Swedish ASP60 powder high speed steel cutter materials |

pneumatic parts | AirTAC |

Screw guide | Taiwan Shangyin |

wire cutting length | 60mm-9999mm |

cutting tolerance | MAP range:1mm+Cut off the degree * below 0.2% |

wire crimping length | 1.5mm-15mm |

Suitable wires | AWG16—28# |

working ability | Within 300MM, 2800-3100PCS/H |

Crimp force | standard 2.0T Other pressure relays need to be customized |

Air pressure | 5.0KG (stability, dry air) |

Power | AC 220V |

Rated power | 3KW |

Detector | 1.terminal exists or not 1.wire exists or not 3.press exists or not 4.air pressure exists or not |

INQUIRY

Categories

Latest News

Contact Us

Contact: Miss.Xin

Phone: 86-13712945876

E-mail: info@Hilong-e.com

Whatsapp:

Add: Guangdong Province, China TianHe District, GuangZhou Num 899