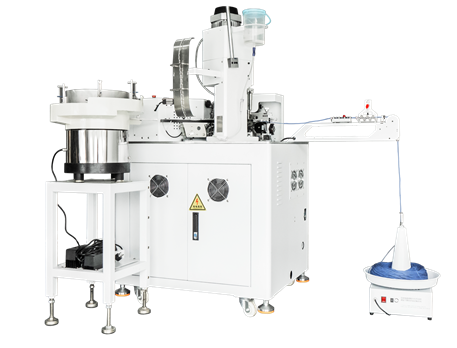

FACTORY Fully Automatic Electronic Wire Cutting Stripping Crimping Machine Terminal Sleeve Insertion Machine

Automatic wire cutting, strippinging, and crimping terminals with one end through a sheath;Tail fully strippinged, fully strippinged, twisted, and tinned

Model: HL-H01

Brand: Hilong

Specifications:

Fully automatic sheath terminal machine - single threading with tin

| Product Features | Automatic wire cutting, strippinging, and crimping terminals with one end through a sheath ;Tail fully strippinged, fully strippinged, twisted, and tinned |

| strippinging range | 0-15MM |

| Twisted wire length | 2-10MM |

| Tinning length | 0-20MM |

| Cutting tolerance | When the wire length is ≥ 1000MM, ± 0.4%. The longer/thicker the line, the greater the tolerance |

| Processing length | 50-9900MM |

| Crimping force | Standard 2T30 stroke (optional 3T)/(optional 40 stroke) |

| Adapt to wires | AWG16-28 # 1007 single electronic wire |

| Adapted mold | OTP card mold (optional flag/European mold) |

| Electrical support | AC 220V 2.5Kw Air: 0.4-0.6MPa |

| Equipment size | Length 750 * Width 950 * Height 1650MM (excluding accessories)/280Kg |

| Pneumatic components | Yadeke Pneumatic |

| Straight slide rail | Shangyin guide rail/Yadeke guide rail |

| Crimping motor | 0.75KW three-phase asynchronous motor, variable frequency control (optional 1.5KW/2.2KW) |

| Action motor | 1 set of domestically produced wire feeding servo, with Yu Xuquan stepper |

| Touch control | 7-inch KINCO color LCD touchable |

| drive control | Jiayuan Intelligence |

| Motor frequency conversion | Jiayuan Intelligence |

| Circuit contro | Chint Electric Appliances |

| program control | ARM eight axis control card |

| Optional accessories | Automatic pay-off reel, conveyor belt, crimpingure monitoring, visual inspection |

| Detection function | Terminal detection, air crimpingure detection, and wire detection ;Fault alarm and crimpingure monitoring (optional) |

| Processing capacity | Within 300MM, 1500PCS/H |

INQUIRY

Categories

Latest News

Contact Us

Contact: Miss.Xin

Phone: 86-13712945876

E-mail: info@Hilong-e.com

Whatsapp:

Add: Guangdong Province, China TianHe District, GuangZhou Num 899